Precision-parts for punching tools, mold making and mechanical engineering

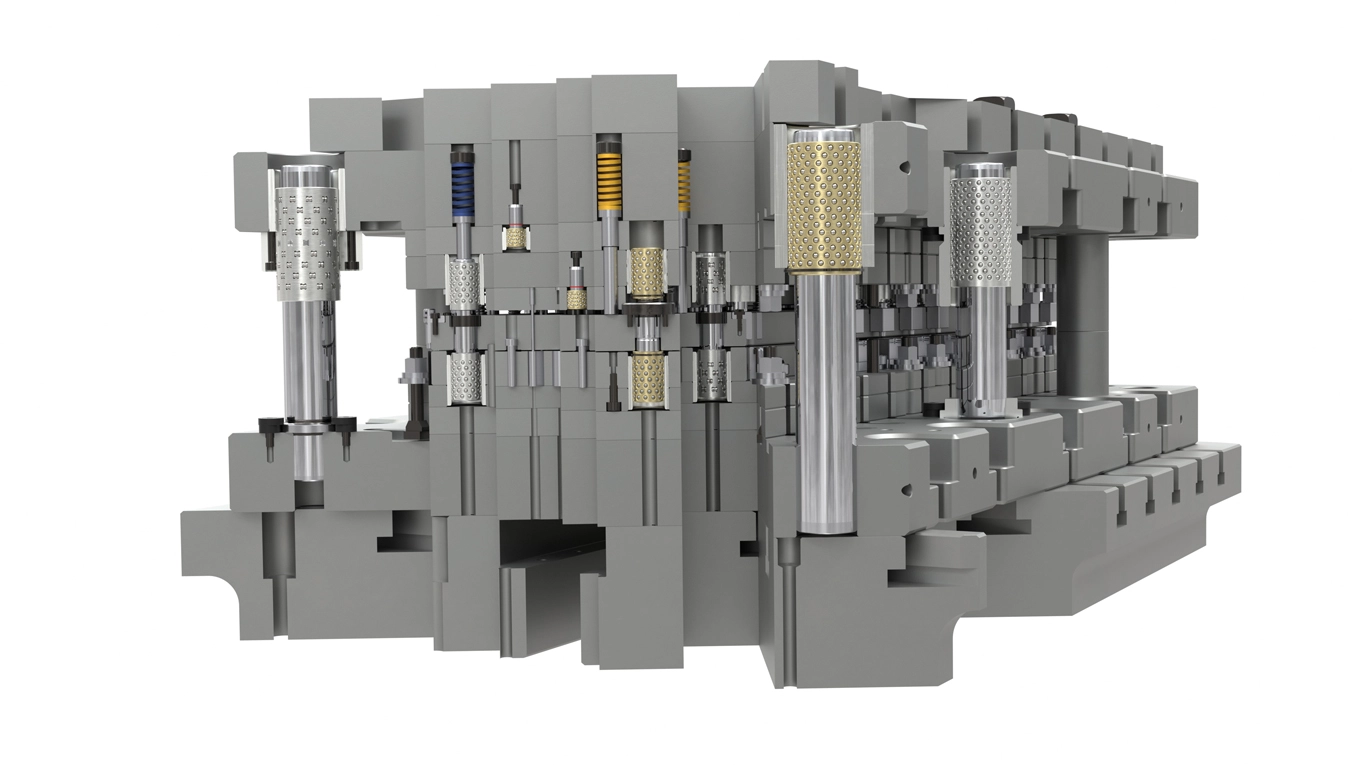

Stripper plate roller guide bushing

Bushing for backlash-fee preloaded roller guide of the stripper plate

Fine centering Plus for the main parting line

The higher-quality alternative to flat centering devices, low-wear due to backlash-free rolling, only minimum quantity lubrication required

Mini fine centering (dyn.) for floating cavity

Backlash-free closing of even the smallest cavities

Mini fine centering (dyn.) for floating cavity

Backlash-free closing of even the smallest cavities

Mini fine centring (stat.) with attached inserts, ideal for half-cut with/without bushing

Quick change of mold inserts, smooth-running - ideal for flexible injection molding

Mini fine centring (static), as a pin connection for attaching the cavity plate

Ensures gentle assembly of the hot runner

Ejector guide with 6500/1 classic, possibly two-stage

Prevents any tilting of the ejector package, smooth and trouble-free rolling even under momentary load

Ejector guide with fine centering Plus 7995 short stroke

The compact short-stroke fine centering as an alternative for guiding the movement of the ejector plates

- Stripper plate roller guide bushing

- Fine centering Plus for the main parting line

- Mini fine centering (dyn.) for floating cavity

- Mini fine centering (dyn.) for floating cavity

- Mini fine centring (stat.) with attached inserts, ideal for half-cut with/without bushing

- Mini fine centring (static), as a pin connection for attaching the cavity plate

- Ejector guide with 6500/1 classic, possibly two-stage

- Ejector guide with fine centering Plus 7995 short stroke

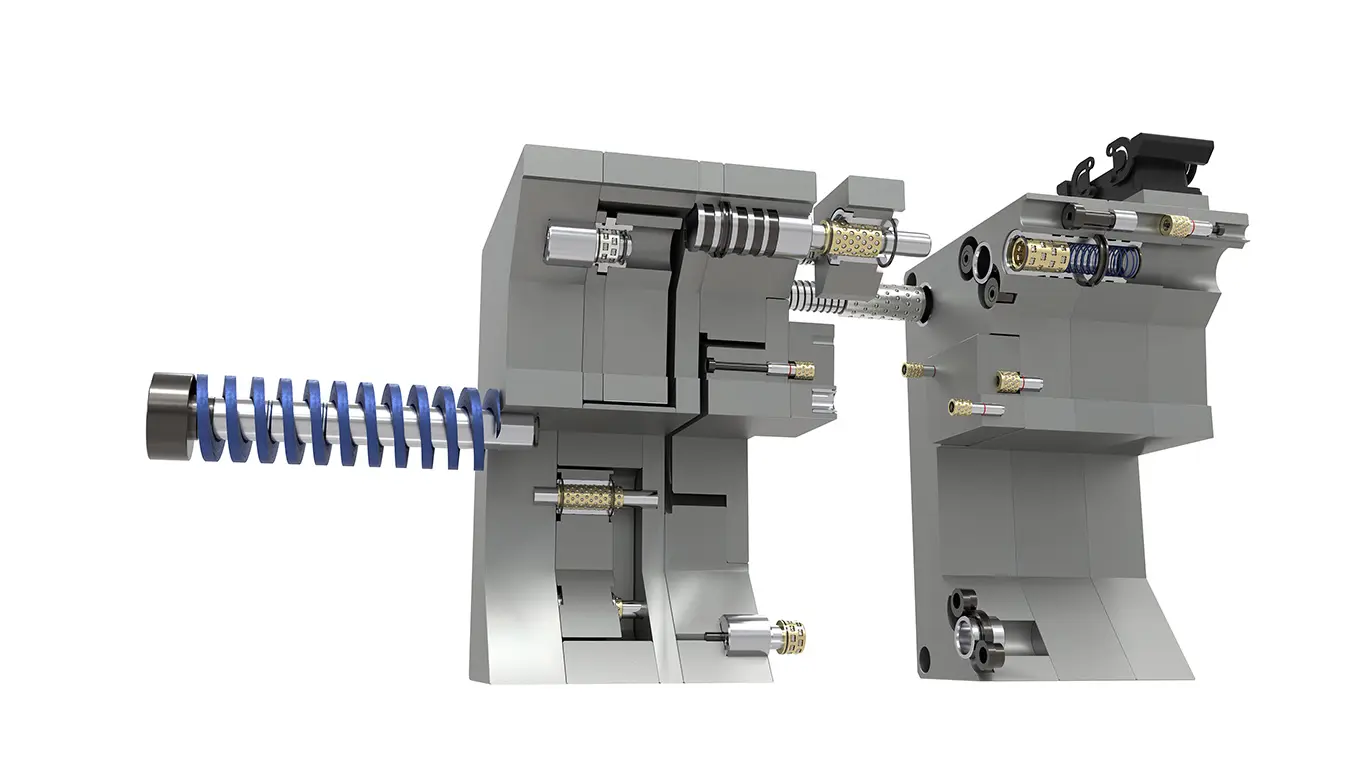

Center flanged inner pillar

The coaxially ground collar of this innovative center flange pillar enables a 100% right-angled installation position and therefore precise adjustment of even the tightest cutting clearances.

Center flanged inner pillar

This center flange pillar is pressed in so that no space-consuming fastening is required. This space- saving innovation provides the tool designer with more space and therefore more flexibility.

Quick-change guide pillar

This type of pillar stands for precision and is often used in rotor-stator tools. The high-precision conical connection minimizes positioning errors. The fatigue-resistant 100Cr6 ball bearing steel ensures a long service life.

Centering element for clamping plate

Simplified disassembly/assembly of tools. The smooth rolling design considerably reduces the manual demands on personnel.

Centering element for punch holding plate

Centering element for punch holding plate Easy handling of the punch holding plate - thanks to the backlash-free, preloaded, easy-rolling mini fine centering, the punch head is positioned perfectly aligned with the guide plate.

Cylindrical outer pillar

Smooth pillars are the classic application for external pillars. Sufficient press-in depth ensures congruent alignment and guidance of the upper and lower parts of the tool.

Flange bushing

The high wall thickness of the bushing ensures rigid and right-angled guidance of the upper and lower parts of the tool.

Collar bushing

The precisely coaxially ground collar surface ensures a right-angled installation position of the guide element and therefore perfect alignment of the upper and lower parts of the tool.

Cylindrical bushing

The bushing standard series for high-precision modular design. Often installed with a light press fit and by means of an adhesive connection.

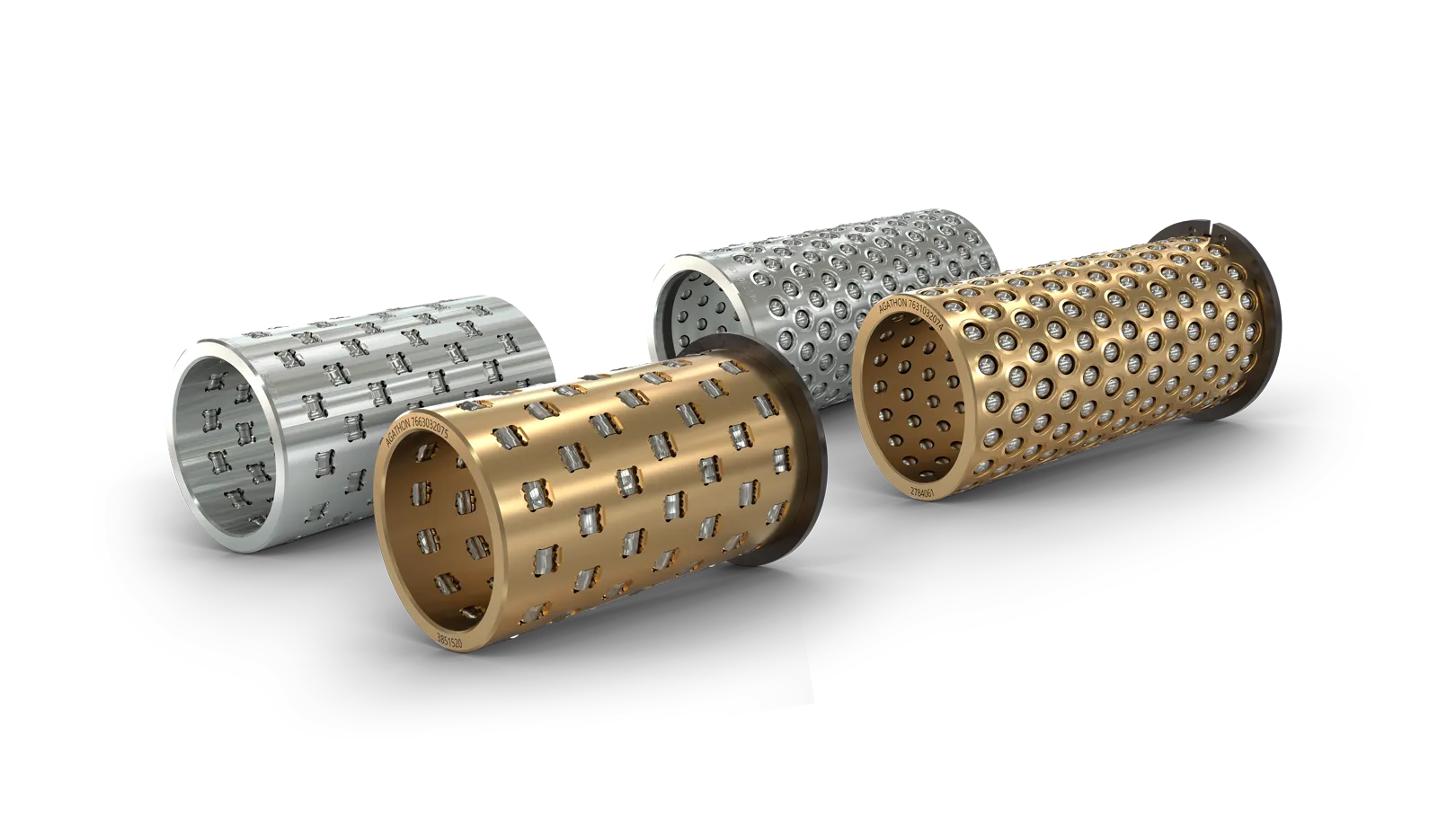

Brass ball cage

This durable solution for high-performance punching is characterized by balanced ball clearance and strong caulking of the rolling elements.

Aluminum ball cage

THE lightweight par excellence for high-speed punching. Durable thanks to balanced ball clearance and strong caulking of the rolling elements.

Aluminum ball cage

THE lightweight par excellence for high-speed punching. Durable thanks to balanced ball clearance and strong caulking of the rolling elements.

Aluminum roller cage

Light and fast with excellent rolling characteristics. High-precision rolling elements ensure a long service life and mastery of even the smallest cutting clearances.

- Center flanged inner pillar

- Center flanged inner pillar

- Quick-change guide pillar

- Centering element for clamping plate

- Centering element for punch holding plate

- Cylindrical outer pillar

- Flange bushing

- Collar bushing

- Cylindrical bushing

- Brass ball cage

- Aluminum ball cage

- Aluminum ball cage

- Aluminum roller cage