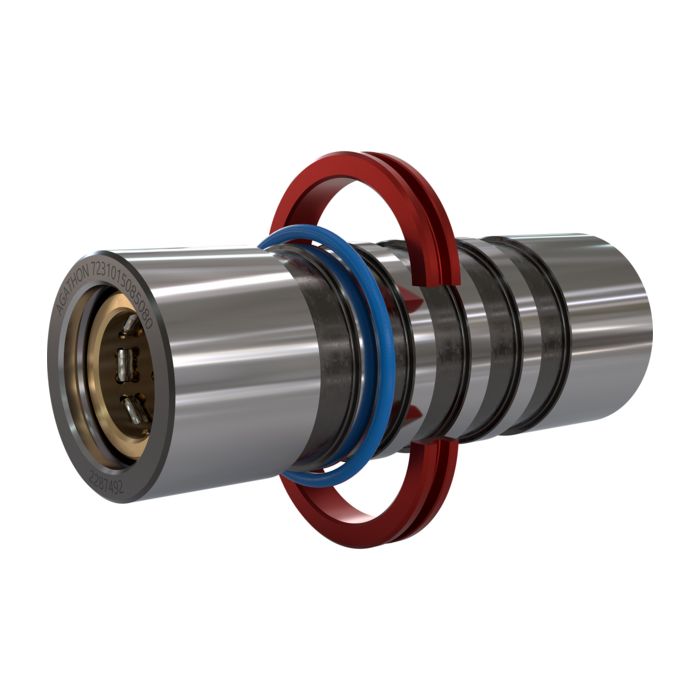

Standard: 7231

Rolling bush system for system guide pillars for minimal wear and precise closing of the tool halves without offset

Advantages

- Highest system precision thanks to backlash-free preloaded profile rollers. Five to twelve times longer service life than conventional sliding guides

- Space saving enables higher production with the same tool size

- Easiest handling: low maintenance, durable and no pairing required despite roller guide

- Displaceable retaining ring (standard 8005) enables use across several plate thicknesses

- Can be combined with all guide pillars from the Agathon product range

- Patented product: more info see here https://www.agathon.com/patents

- Contains products containing lead. For further information see: https://www.agathon.com/REACH

Combined guiding and centering

Guiding and centering concept

- Combination of two different systems in the mold

- The guide pillars only take over the coarse alignment of the mold during most of the closing movement

- Only on the last millimeters of the closing stroke do the flat centering devices take over the fine alignment

- This can be a problem with long, or sensitive mold areas

- The flat guides are subject to relatively high wear

- The Agathon Guiding System Plus takes over all guiding and centering tasks with just one assembly over almost the entire clamping stroke

- Smooth and highly precise guidance thanks to preloaded profile roller cage

- No jerky sliding during mould movements

- Easy handling: Low maintenance, durable, no pairing required despite roller guide

- Nearly wear-free

Conventional approach

The Agathon concept

Advantages of the Agathon concept

- Four main guides and four flat centering devices are required

- The production of the pockets for flat centering devices is complex, time-consuming and imprecise

- Two systems in the tool require valuable space

- Precision depends on manufacturing tolerances and wear condition of the guiding and centering elements

- High lubricant and maintenance requirements

- Dirt ingress due to abrasion and particle formation

- Pocket production for flat centering is no longer necessary, which saves time and costs

- Enlarging the working area by up to approx. 30% for additional cavities, slides or tempering

- Thanks to backlash-free preloaded guides with profile rollers, precision remains at the highest level over the entire service life

- Low lubricant and maintenance requirements increase the productivity of the system, reduce maintenance costs and protect the environment

Key features and highlights

- The roller bushing can be adapted to different plate thicknesses by positioning the retaining ring accordingly

- The ring, which can be reordered as a spare part, can be used with roller bushing system 7231 and system guide pillar 6701

- Safe fixing thanks to heat-resistant O-ring (up to 200 °C)

- Tool is already centered when the preload is reached

- Abrasion on spotting surfaces and plunging cores is prevented

- Tool service life is significantly increased

- Minimum quantity lubrication is sufficient

- Rolling bush with brass profile roller cage allows cleaning in an ultrasonic bath and temperatures up to 170 °C

- Optimal for clean room, high-precision, micro-injection molding and high-temperature applications

- Significantly higher travel speeds and therefore higher production output possible

Advantages at a glance

- Thanks to this concept, only one size is required in stock. The guide can continue to be used if the tool and plate thicknesses change

- Compatibility: retrofitting to tools is possible without reworking plates

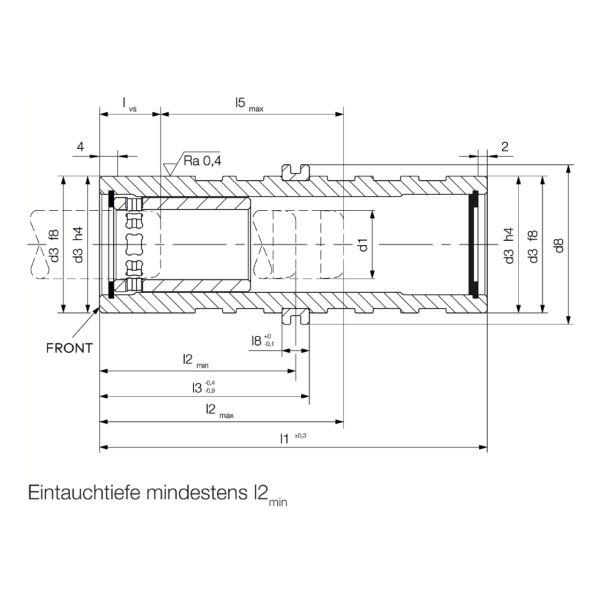

- No pairing required: Any bushing of the appropriate diameter of standard 7231 can be combined with any system guide pillar of standard 6701 of the appropriate diameter from the Agathon product range. Attention: Do not exceed length l2max

- Spare parts available from stock

- The division of tasks between main guide and end centering is eliminated

- Simplification of the tools: Fewer components and less space required on the clamping surface, significantly lower manufacturing and assembly costs

- Thus more cavities and higher productivity on the same clamping surface

- Existing flat centering devices can be removed when retrofitting the Agathon Guiding System Plus

- Backlash-free preloaded guide with profile roller cage ensures maximum precision and part quality over the entire service life of the tool

- The service life is 5-12 times longer compared to conventional systems

- High process reliability avoids rejects and production stops

- Lower maintenance requirements and higher productivity

Scope of delivery: incl. 1 ring clamp standard 8005 in the respective diameter. Material of bush and rollers: 100Cr6 (1.3505), hardened 62-64 HRC Material of cage: brass CuZn39Pb3 (2.0401) Temperature resistance: up to approx. 170°C

Technical data

Dimensional drawing Installation tolerances

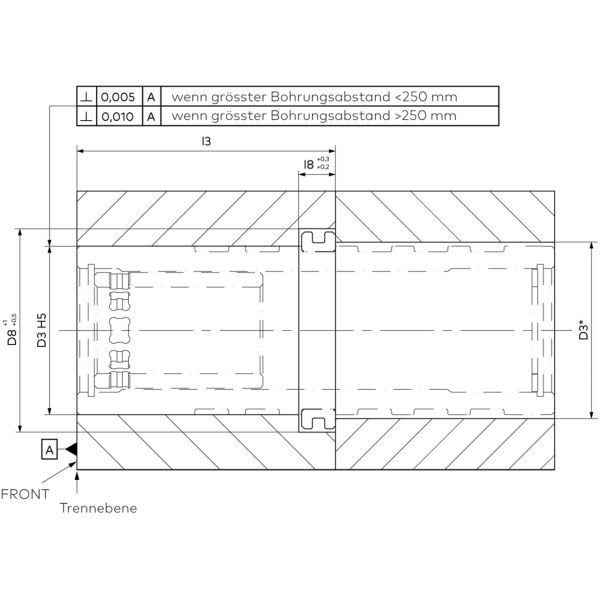

Accuracy requirements

- The pillar and bushing are installed in bores with tolerance H5

- Alternatively, if less accuracy is required, the tolerance H6 can be used

- Pay attention to the installation direction (FRONT)

- If the largest hole spacing of the main pillar is less than 250 mm, the perpendicularity of the locating hole to the parting line should be <0.005 mm per 100 mm length of the guide pillars.

- If the largest hole spacing of the main pillar is greater than 250 mm the perpendicularity of the mounting hole to the parting plane should be <0.010 mm per 100 mm length of the guide pillars.

- If the largest hole spacing of the main pillar is less than 250 mm the positional accuracy should be <0.01mm (i.e. ±0.005 mm)

- If the largest hole spacing of the main pillar is greater than 250 mm the positioning accuracy should be <0.02mm (i.e. ±0.01 mm)

- Recommendation for best performance: pre-drilled plates with sanding allowance to the desired tolerance or have plates produced with the recommended tolerance

Installation tolerances:

Rectangularity:

Position tolerances:

* = Depending on the required accuracy, the following plates can be be cut to size for easier assembly

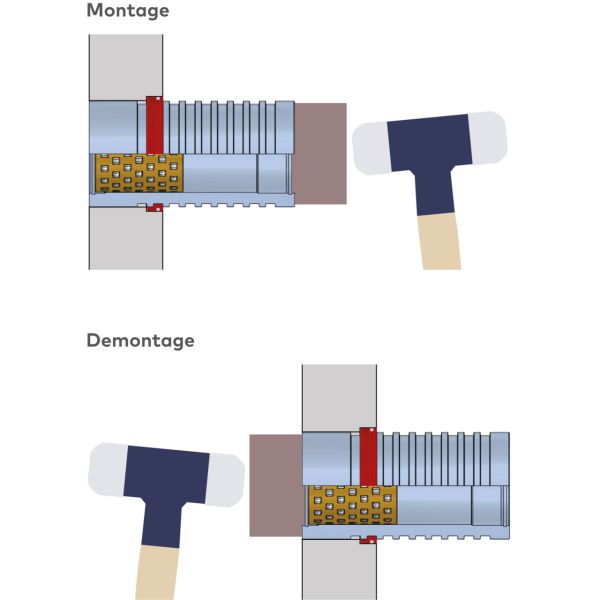

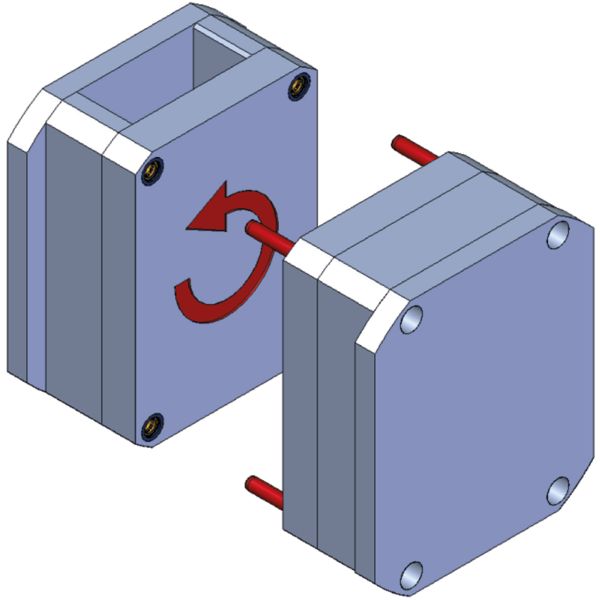

Image installation and removal

Assembly, disassembly and maintenance of the Guiding System Plus

- Clean and remove corrosion protection before assembly, then lubricate

- Position the retaining ring correctly, insert the O-ring

- Tap into the fit with light blows, use a rubber mallet or spacer

- Do not tap the retaining ring or ring clamp

- Use a rubber mallet or spacer

- Do not tap the retaining ring, ring clamp or cage

- Do not pull on the ring clamp

- Regularly rotate the bushing and pillar by 60°

- First remove the old grease completely, then apply new grease

- Minimum quantity lubrication is sufficient

- When replacing the O-ring, observe temperature resistance (FKM)

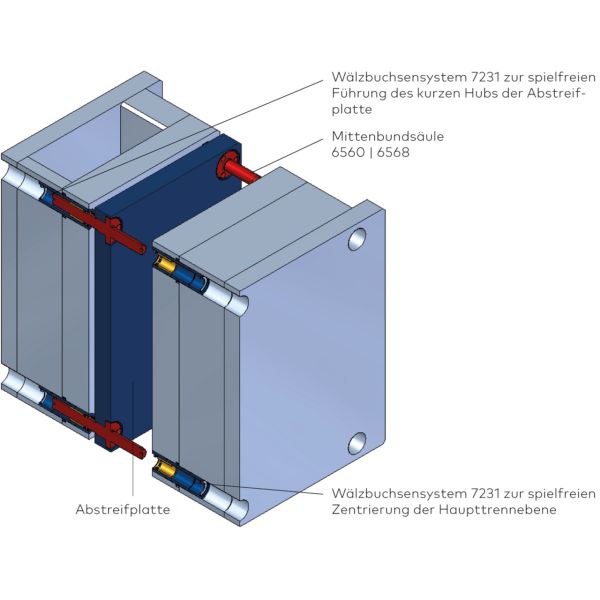

Führung einer Abstreifplatte

Guidance of a wiper plate on the column

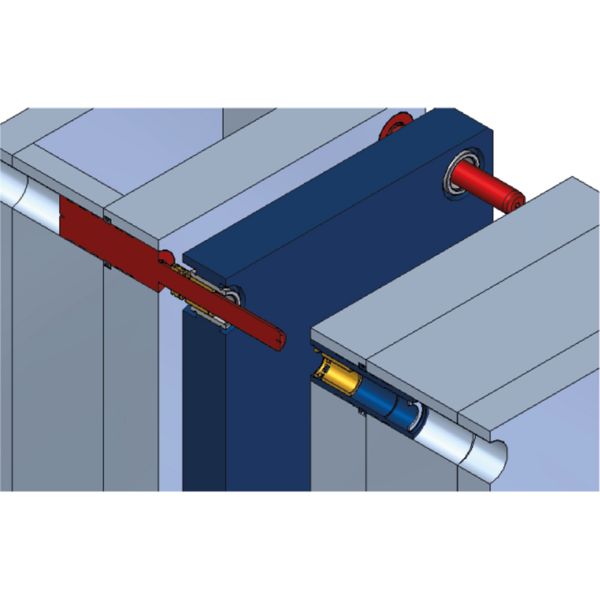

Guidance of ejector plates (short stroke)

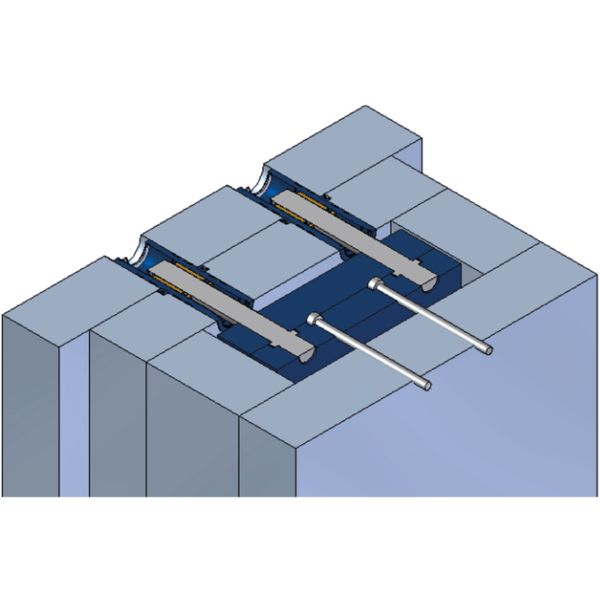

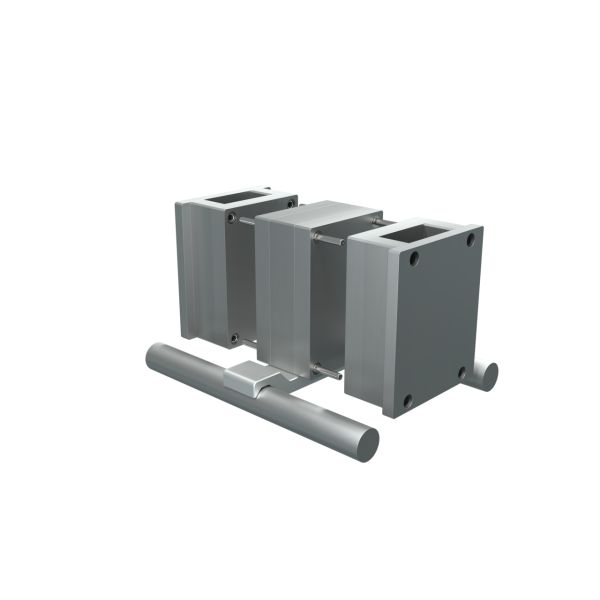

Main guide in the stack mold

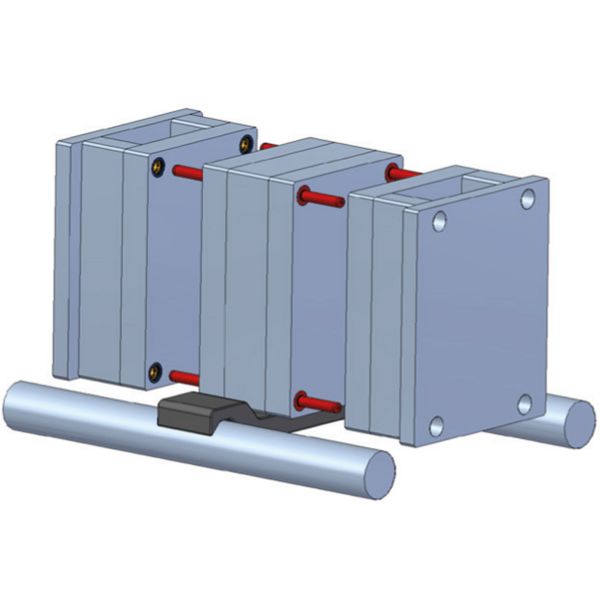

Main guide for turning tools

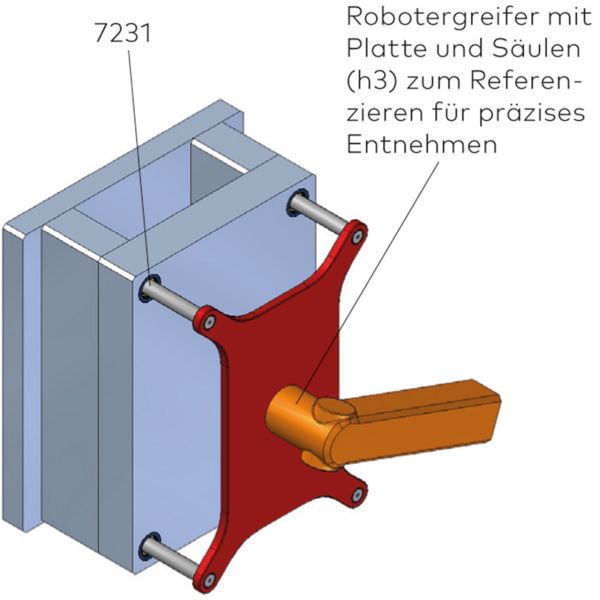

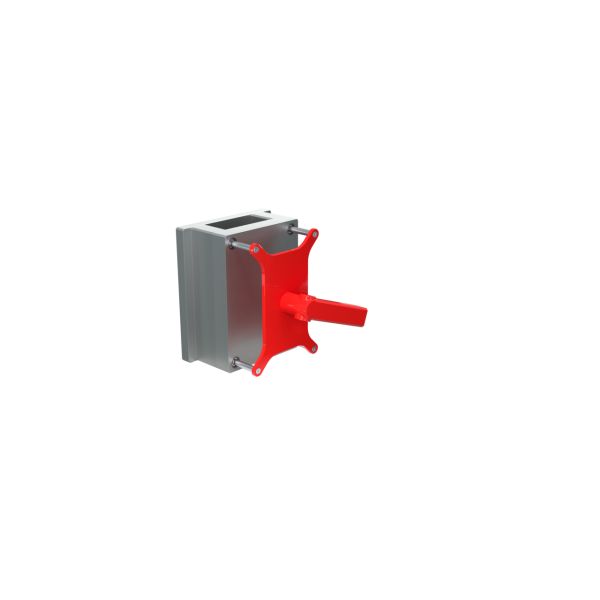

Centering for handling

| Application type 1 | Center, Lead |

|---|