Guide pillar straight

Norm: 6500 Ø18

Ejector guide pillar for high-precision plug & play solutions with maximum durability. The assembly with ball cage and bushing creates a backlash-free, preloaded and smooth-running guide that reliably prevents the ejector assembly from tilting.

Advantages

- Jerk-free movement, no tilting of the ejector assembly even with very asymmetrical force transmission

- Backlash-free preload enables precise movement sequences

- Low wear, therefore long service life and low susceptibility to faults

- High process reliability avoids blockages, rejects and production stops

- Only minimum quantity lubrication required

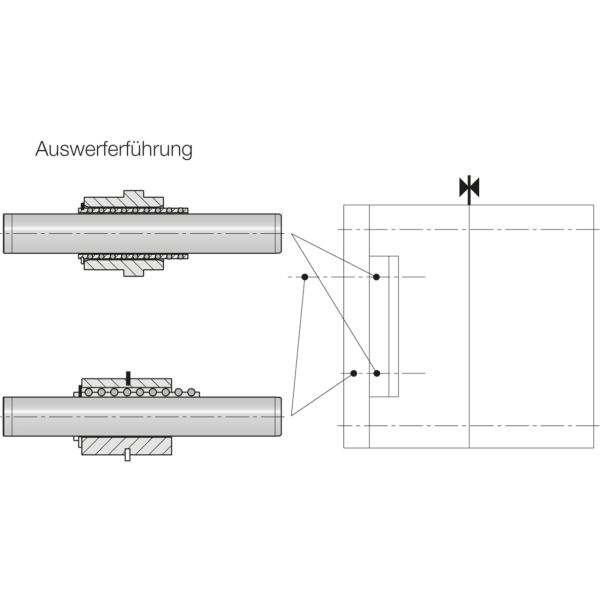

Ejector plate guide

Application

In practice, simple sliding guides are often used for the applications described. However, these are often subject to considerable wear, which can lead to cold welding and jamming of the mechanism. This results in unplanned production downtime and high maintenance costs. The Agathon roller guide, on the other hand, has excellent emergency running properties.

Benefit

Functionality

The guideways are subjected to high loads on one side, particularly under moment loads, which can lead to the permissible surface pressure (pzul) being exceeded locally. This results in abrasion and the risk of cold welding, which can lead to blockages. In contrast to sliding guides, a roller guide can also roll under high moment loads, so that no such failures need to be feared.

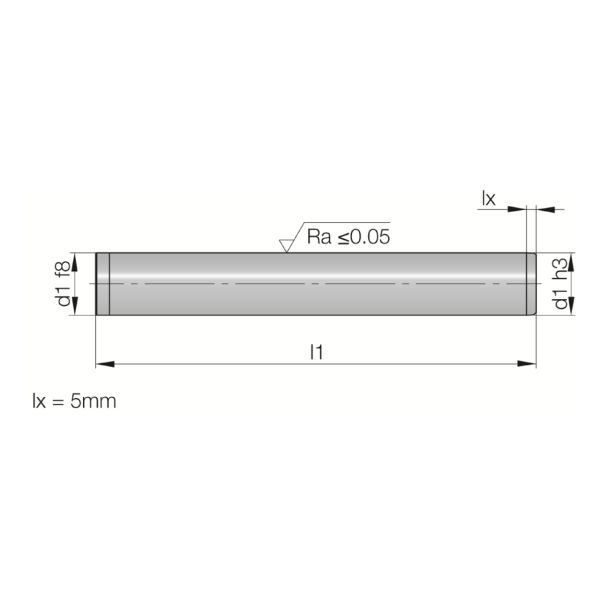

Material: 100Cr6 (1.3505), hardened 62-64 HRC

Technical data

d1

=

Pillar diameter, tolerance h3, precision ground

l1

=

Pillar length

| Application type 1 | Lead |

|---|